Steelmaking and coke

Quarry (crushed stone)

Cement and ready-mixed concrete

Asphalt

Civil engineering

Thermal power plant

Recycling

Water treatment

Logistics

Paper and pulp

Designing a safe and highly reliable pulley with thorough strength calculations for all members

Design engineers specializing in pulleys for belt conveyors check not only the external dimensions of the products, but also the operating environment of the entire equipment in advance, such as the captain of the conveyor, the head, and the specifications of the electric motor, and calculate load conditions for each product and extract concerns.

In addition, we conduct thorough strength calculations not only for the shafts, but also for the shells, side plates, bosses, bearings, and other parts.

Optimal material selection based on load conditions enables long-term use

Pulleys are relatively expensive, and in the unlikely event that they break, they are important parts that have a significant impact on their operation.

Therefore, we do not use unnecessarily thick, high-cost members in the selection of pulley materials, but grasp the properties of materials from strength calculations based on load conditions and set the optimum members and dimensions that do not reach the calculated fatigue limit.

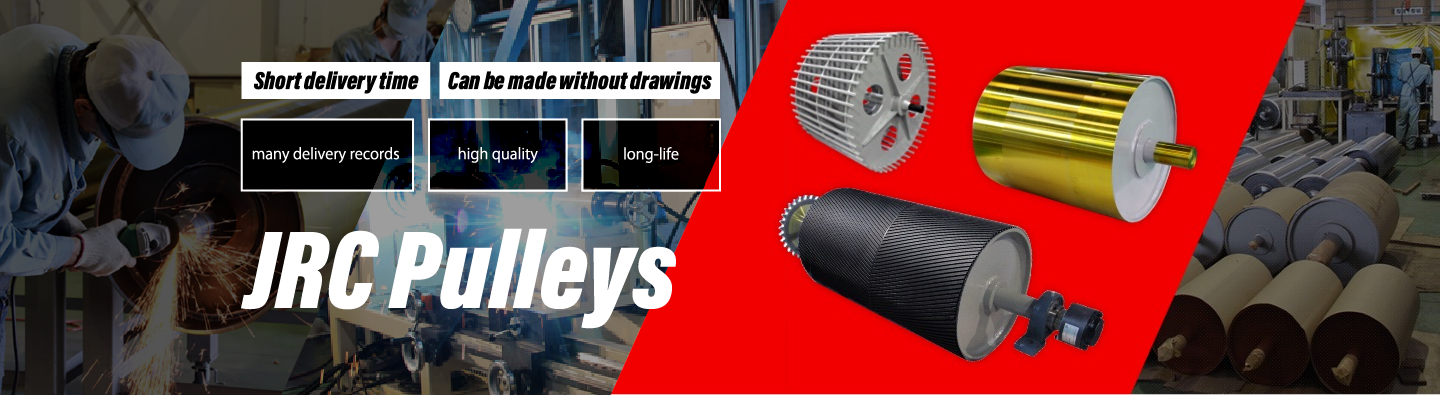

Short-time delivery for small lots and special products

Our North Kanto Plant (Saitama Prefecture) has a large number of facilities specialized in pulley production as the country's only specialized plant for pulleys for belt conveyors.

In addition to the Hokkaido Plant, we also manufacture pulleys at the Hokkaido Plant (Asahikawa City) and the Kyushu Plant (Kagoshima Prefecture) as well as at other cooperative plants, enabling us to respond quickly to a wide variety of pulley production.

Accurate quality is guaranteed through thorough inspection of all parts.

In order to deliver products of reliable quality to all our customers, we thoroughly conduct "full inspection" of pulleys manufactured by us.

In addition to in-process inspections, we carry out a wide range of inspections, from accessories inspections to rotation runout and balance inspections, PT and UT (non-destructive inspections) and other more detailed inspections to ensure reliable quality.

Even if you don't have a drawing, our professional staff will check the measurements and specifications at the customer's site.

Regarding existing pulleys, if there are no drawings or other materials left at the time of new installation, we do not know when, which manufacturer, what dimensions and specifications were manufactured, and there are many customers who suffer from trouble.

In such cases, our specialist staff can also visit the customer's site to check the dimensions and specifications.

One-stop for installation of bearings, sprockets, rubber lagging construction, etc.

Not only bearings, but also transmission components such as sprockets and couplings of drive pulleys, can be incorporated into reverse prevention devices.

Rubber lagging (lining) can also be constructed with high quality and short delivery time, enabling one-stop supply of pulleys as "final finished products" required by customers.

| Pulley diameter | φ1500 |

|---|---|

| Pulley width | 3000L※ |

| Shaft length | 4000L※ |

| Weight | 5000kg |

※ The maximum pulley width and shaft length are 7000L in total.

Due to the Item consistency dimensions and structure of the pulley, it may be difficult to manufacture even if the dimensions are within the above range, depending on the balance and shape. Conversely, even if the dimension is outside the above range, it may be possible to manufacture. The above figures are only a guideline, so please feel free to contact us first.