We have an integrated support system that covers everything from proposals for improvement that capture the essence of each customer's problem to the implementation and verification of countermeasures.

Taking advantage of the experience gained through many belt conveyor improvements in a wide range of industries,

we provide customers with solutions that generate continuous benefits.

JRC's ability to make proposals and technical capabilities cultivated over many years as a belt conveyor professional will provide total solutions to your on-site issues.

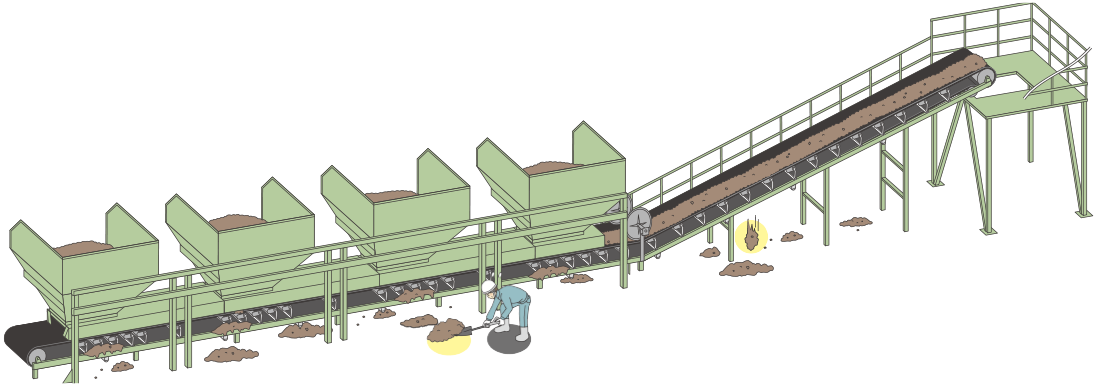

Improve reduced productivity!

Conveyor equipment operates stably and productivity improves.

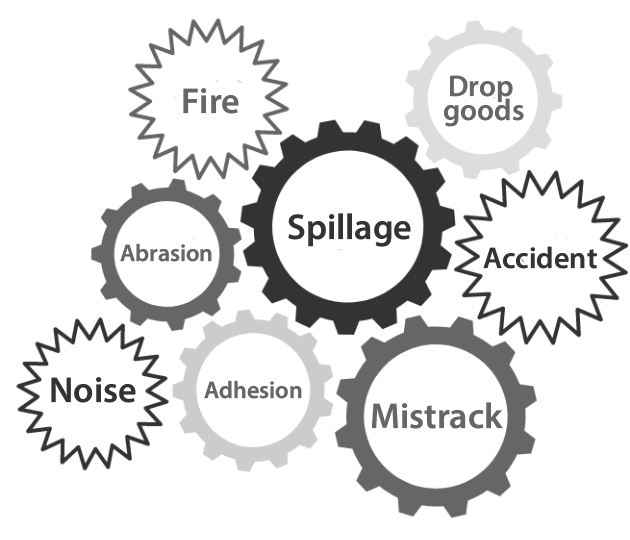

Stable operation without stopping equipment is a very important theme at the production site. The JRC solution helps you increase your site's productivity by helping to reduce maintenance hours required for equipment shutdowns due to belt mistracking and mine cleaning, etc., and by contributing to increased production volumes.

Reduce extra cost!

This reduces the frequency of cleaning and replacement, contributing to cost reduction.

JRC solutions can be expected to reduce labor costs for cleaning and maintenance required for the entire facility, as well as extra costs for repairing and replacing components, etc. Furthermore, we expect various ripple effects, such as the effective use of human resources and the reduction of adoption costs by improving the on-site environment.

Reduces time and effort!

The complicated roller replacement work can be done easily and efficiently.

In many cases, replacing the rollers involves heavy work, such as loosening the belt tension and lifting it up with a jack-up or removing the stand itself. JRC offers a large lineup of products that can easily and safely perform complex roller replacement operations, reducing the times and labor involved.

Reduce the risk of accidents!

Hazardous work opportunities are reduced and job site safety and safety awareness are improved.

Conveyors require a variety of maintenance tasks, including belt mistracking and offset adjustment, removal of deposits, and cleaning of deposits. The mission of JRC is to realize conveyors that do not require customers to force these tasks during operation, and we are actually achieving the elimination of dangerous work opportunities and hazardous locations at many sites.

Longer life of equipment and components!

Constituent parts such as rollers and belts last longer due to stable operation due to the proper placement and introduction of products.

After ascertaining the specifications and characteristics of the customer's equipment, JRC will not only simply replace existing equipment, but also take measures with highly functional and highly maintainable products that have been developed in recent years, and switch from the conventional ex-post management to preventive maintenance management, thereby contributing to the longevity of equipment and components.

Continuous on-site PDCA with the cooperation of customers and JRC will improve the safety and productivity of the entire conveyor facility and create new cost-benefits.

In addition, through a series of solutions, knowledge of conveyor operation is accumulated, so that it can be applied to other lines, contributing to environmental improvement and cost reduction on a corporate scale.