solution products

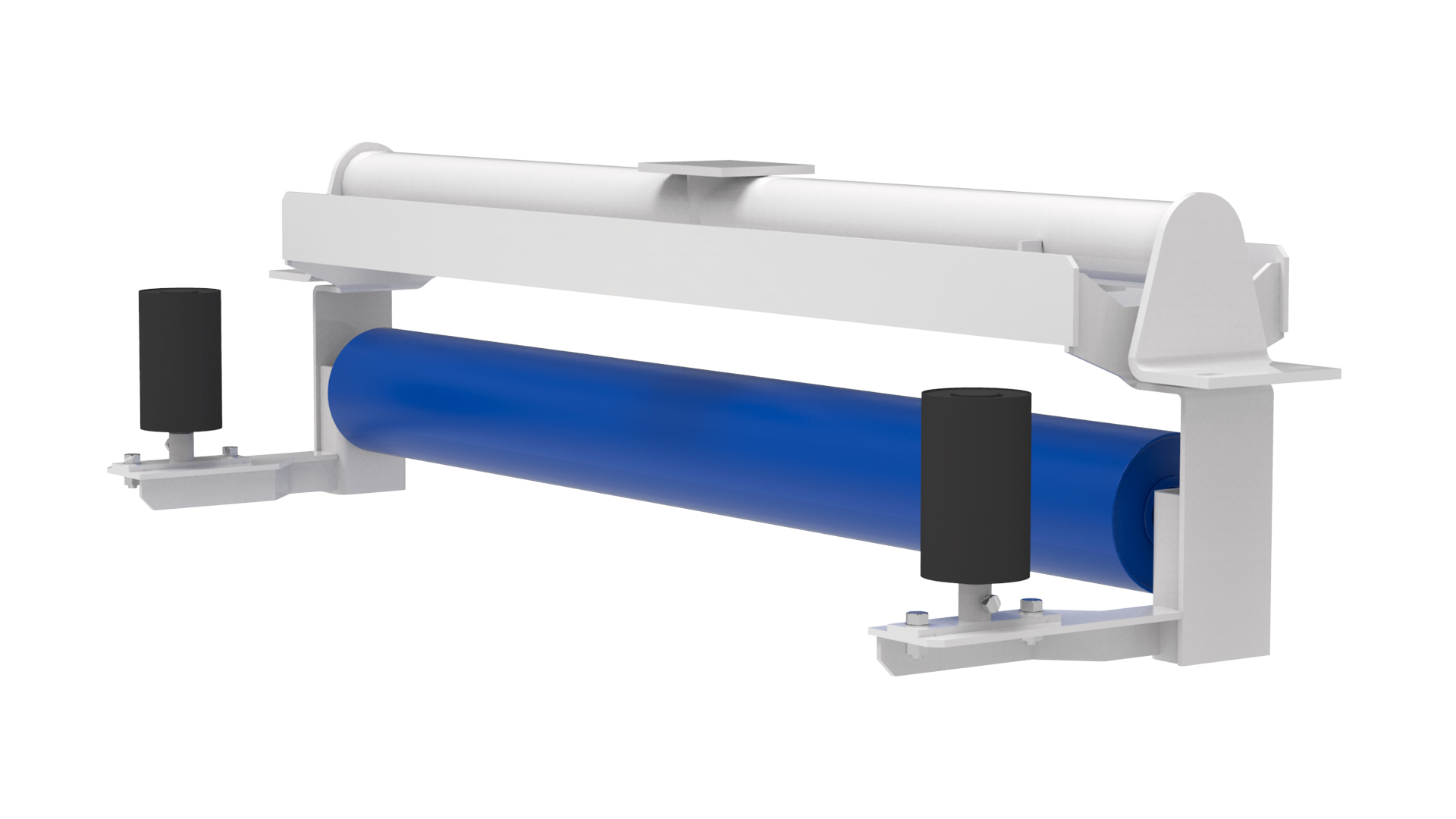

TRAINING CARRIER IDLER (HIGH SPEC)

The frame turning performance has dramatically improved and evolved!

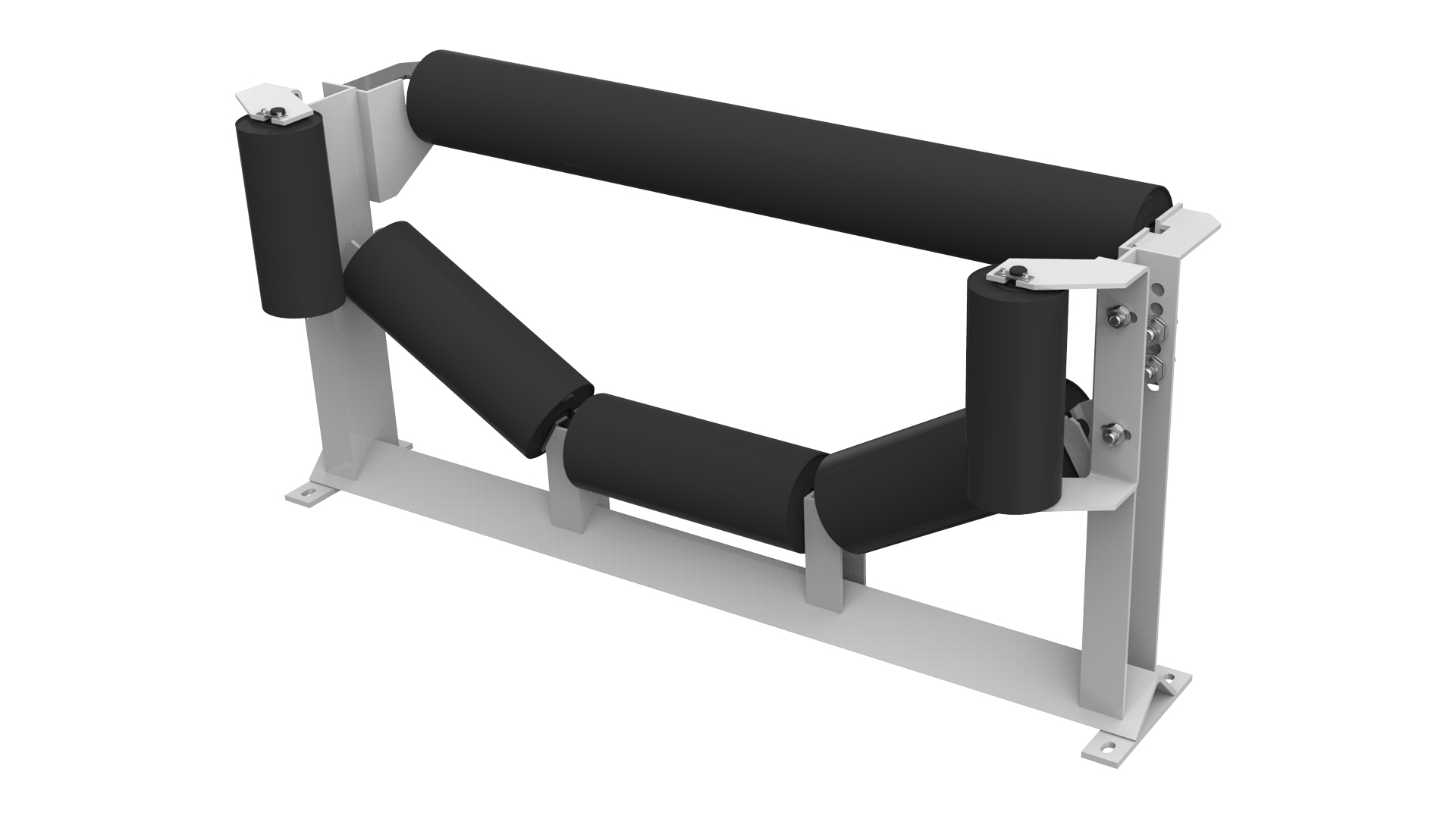

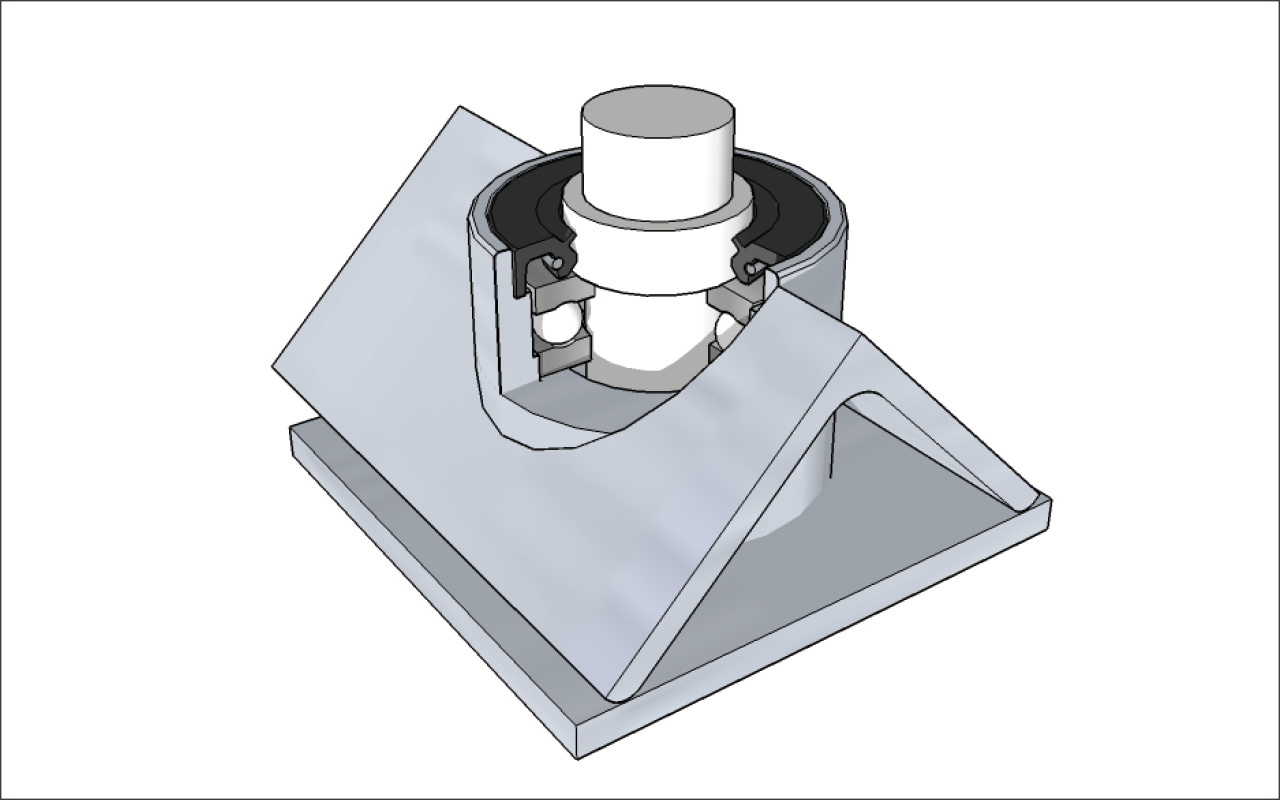

The entire idler is structured to pivot at a fixed angle around the center pin.

When the belt comes into contact with the guide roller during belt mistracking, the frame rotates and returns the belt to the center of the conveyor by the component of the generated resistance.

Product Features

-

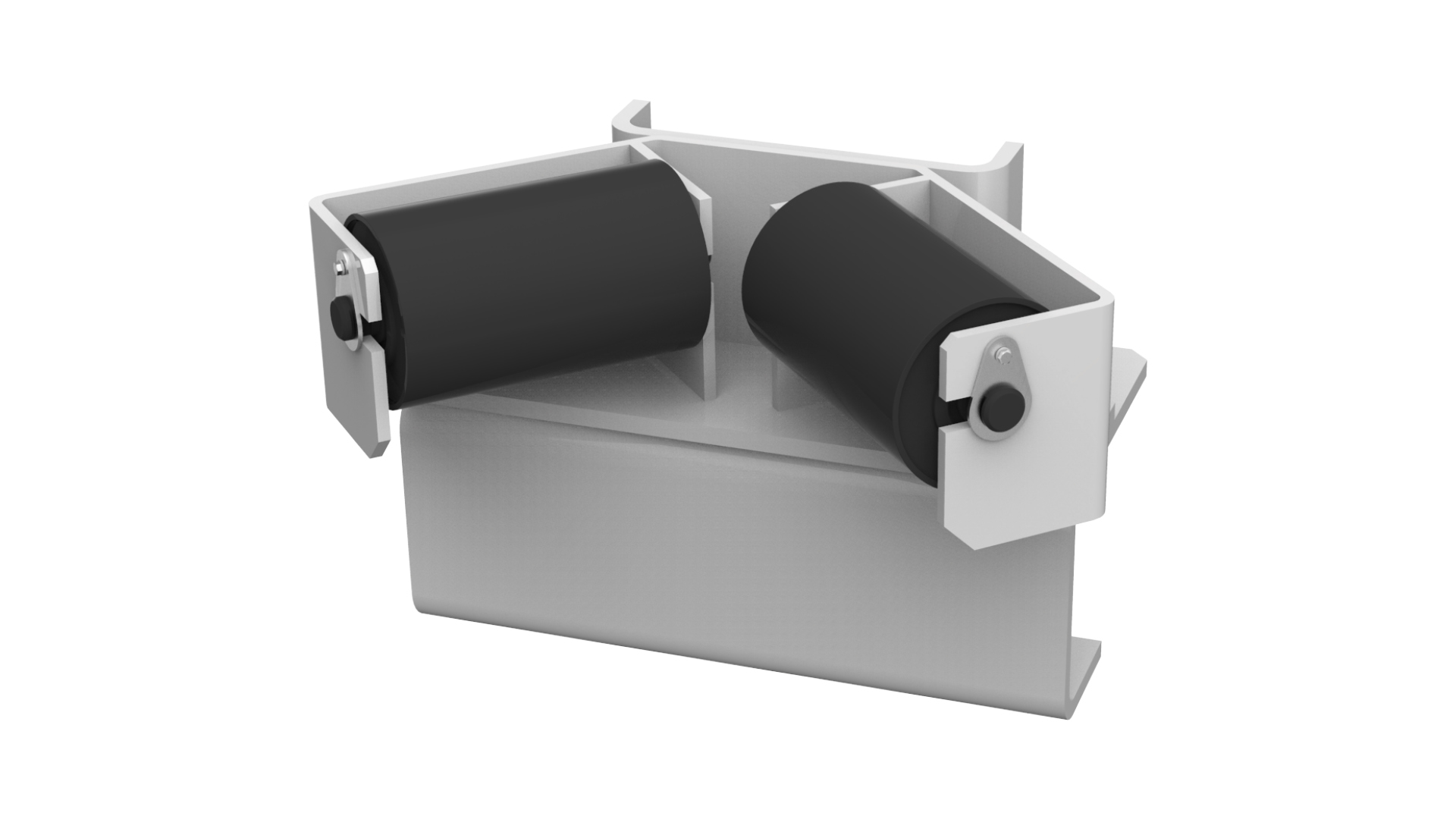

Improved performance and strength of slewing parts

The use of thrust bearings in the slewing section and the thick reinforcement of the center pin has made it possible to swivel the frame with a smoother and more stable.

-

Higher slewing performance with support bearings

The support bearings (two on one side) are adopted at the lower part of the slewing frame to further smooth the motion during slewing and enable stable mistrack adjustment.

-

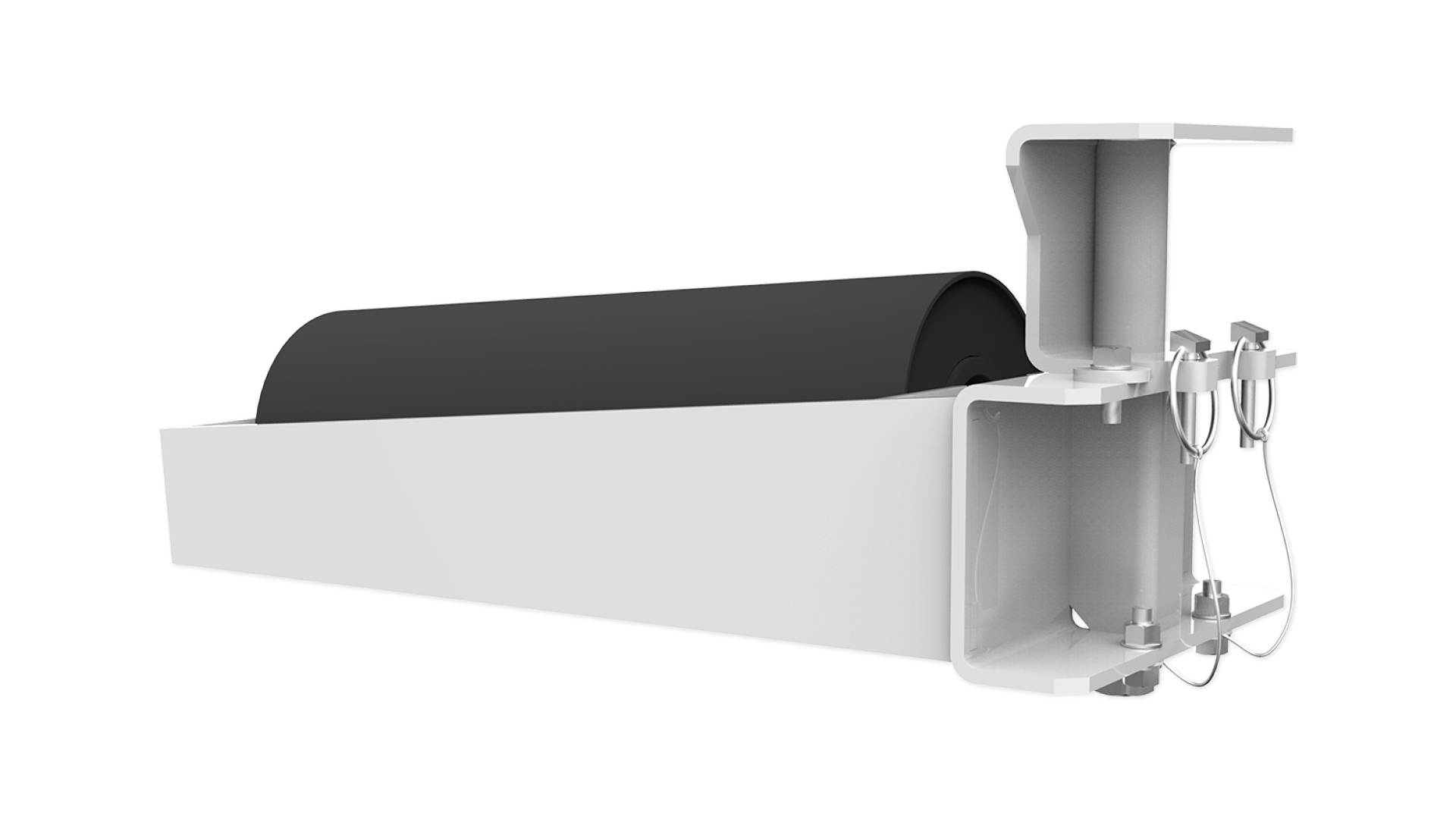

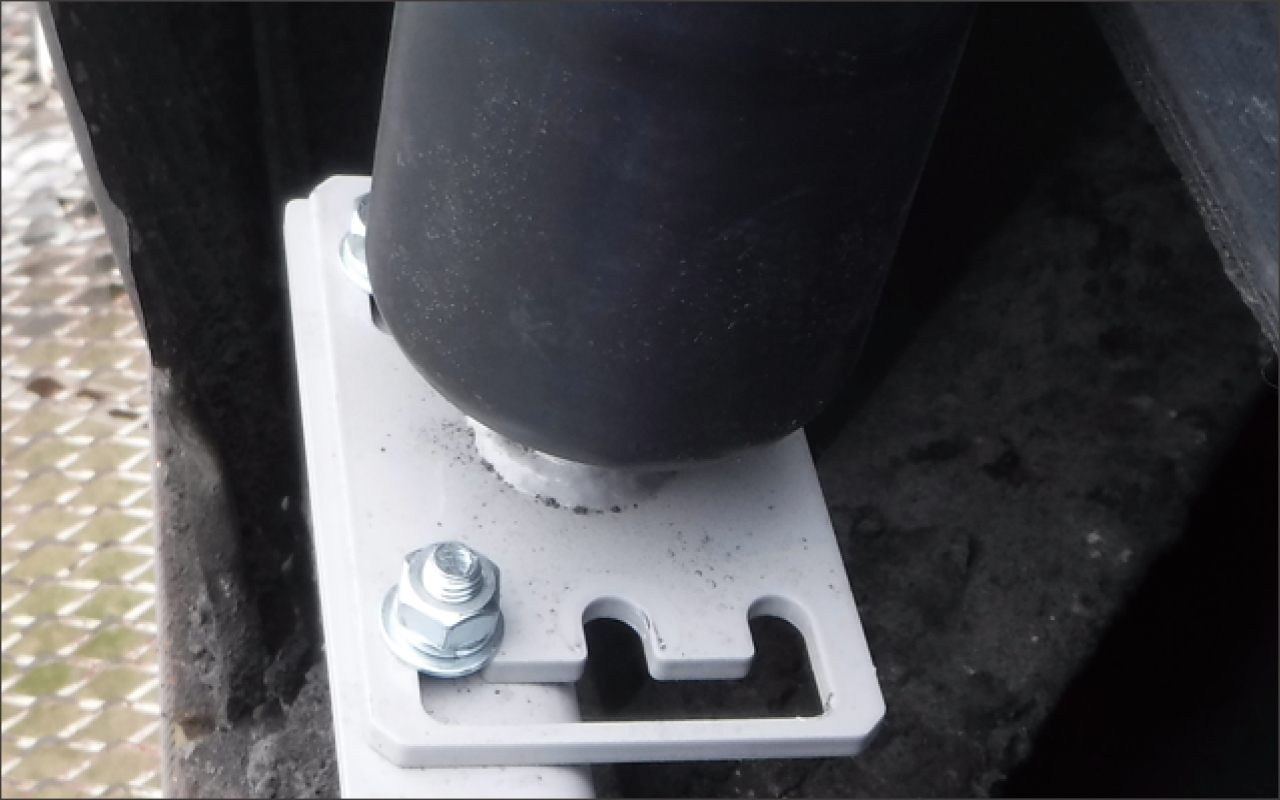

Mistracking allowance can be adjusted in three stages!

※An "E" shaped long hole for adjusting the meandering allowance is introduced in the guide roller.

The amount of meandering can be adjusted in three stages to reduce belt damage and premature roller wear.

Customer's voice

※There are fewer emergency shutdowns and the occupancy rate has gone up!

※We installed new equipment on the conveyors for transporting sugar mills unloaded from ships to storage facilities.

In the past, due to belt meandering, the meandering detector was activated 3 ~ 4 times a day, the conveyor stopped urgently, and the workers were busy checking and releasing each time, which was very troublesome.

This product reduces the frequency of emergency shutdowns & increases availability!

Because of the positive results, we also installed it on other conveyors we were transferring to!

※Industry: Sugar production

Conveyance: raw sugar

Belt width: 1200 mm

Belt speed: 118 m/min

Carrying capacity: 700 t/h

Captain: 88 m