solution products

IMPACT SLIDE

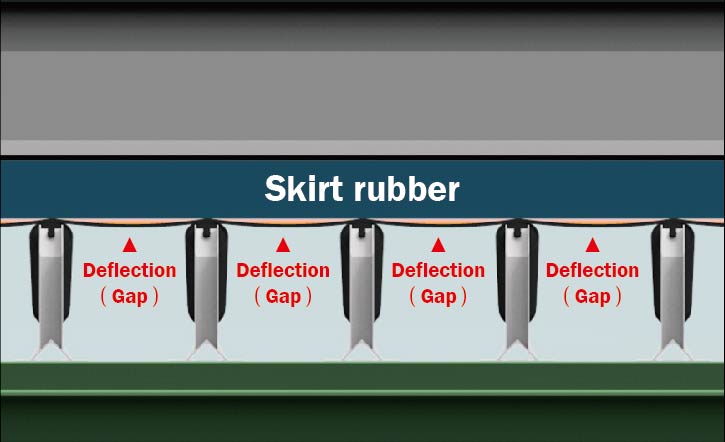

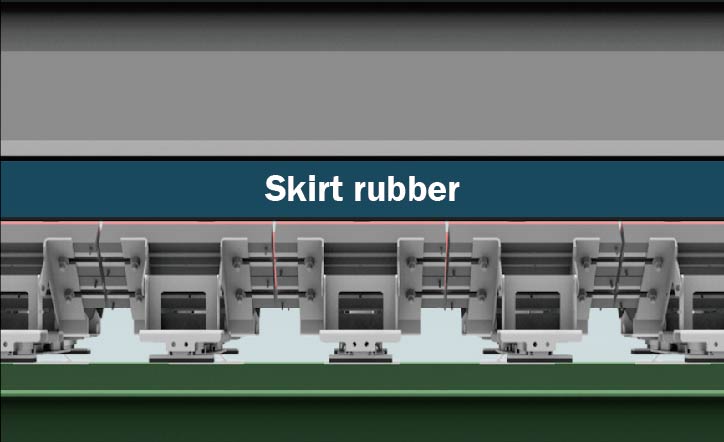

Blow over is greatly reduced by eliminating gap with skirt rubber

This product eliminates the gap with the skirt rubber due to belt deflection between rollers by replacing the conventional trough roller with a slide bar with low friction resistance, and reduces spilled or blown load on the conveyed load.

Before - After

Before

Before

The belt deflected and gapped easily between the belt and the skirt rubber, causing spills or blows over of conveyed materials.

After

After

Slide bars eliminated gaps with skirt rubber and reduced spills and blows of conveyed materials.

Product Features

-

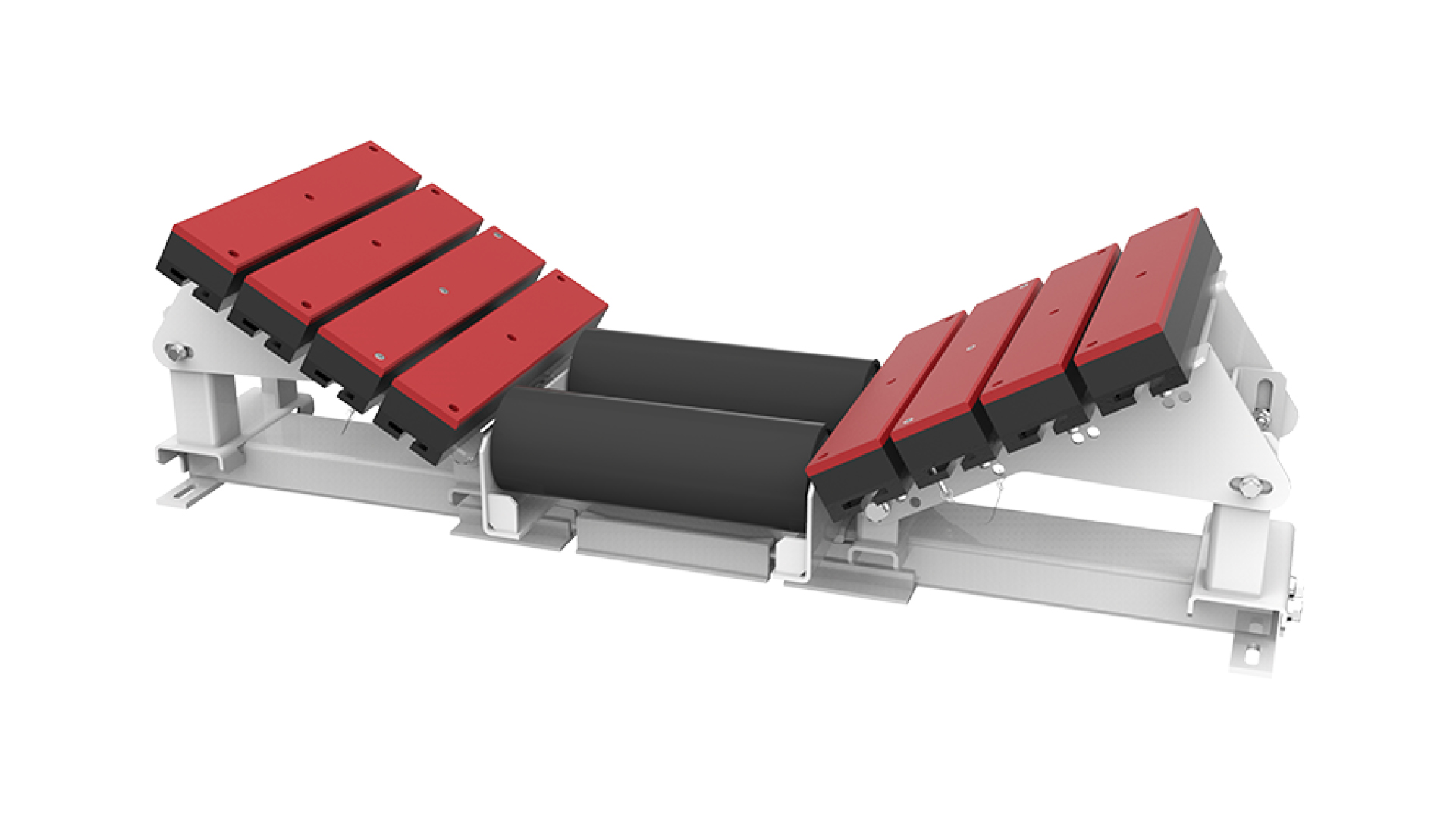

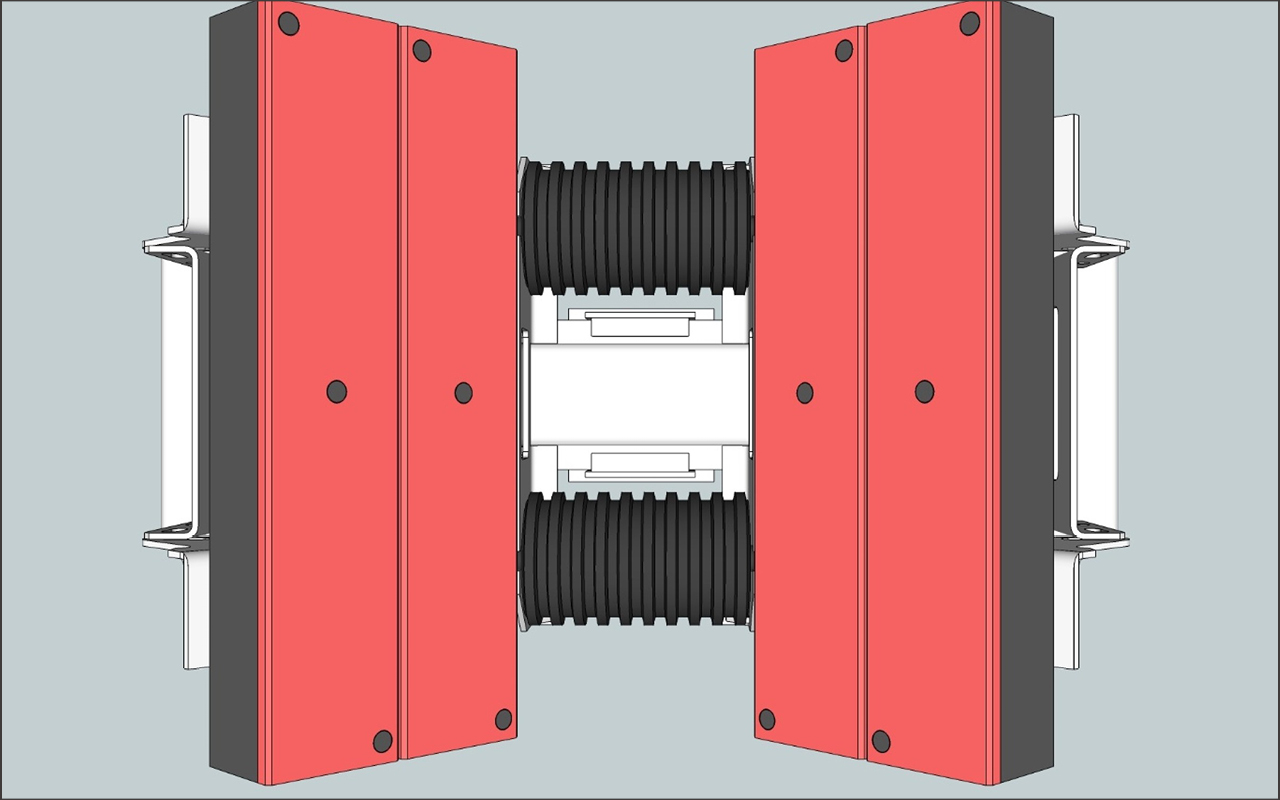

Right and left slide bars are used.

The right and left slide bars, which are excellent in impact resistance and abrasion resistance, have a lineup of 500mm and 750mm in width, making them easy to follow the shape of the skirt rubber, and also give consideration to maintainability.

-

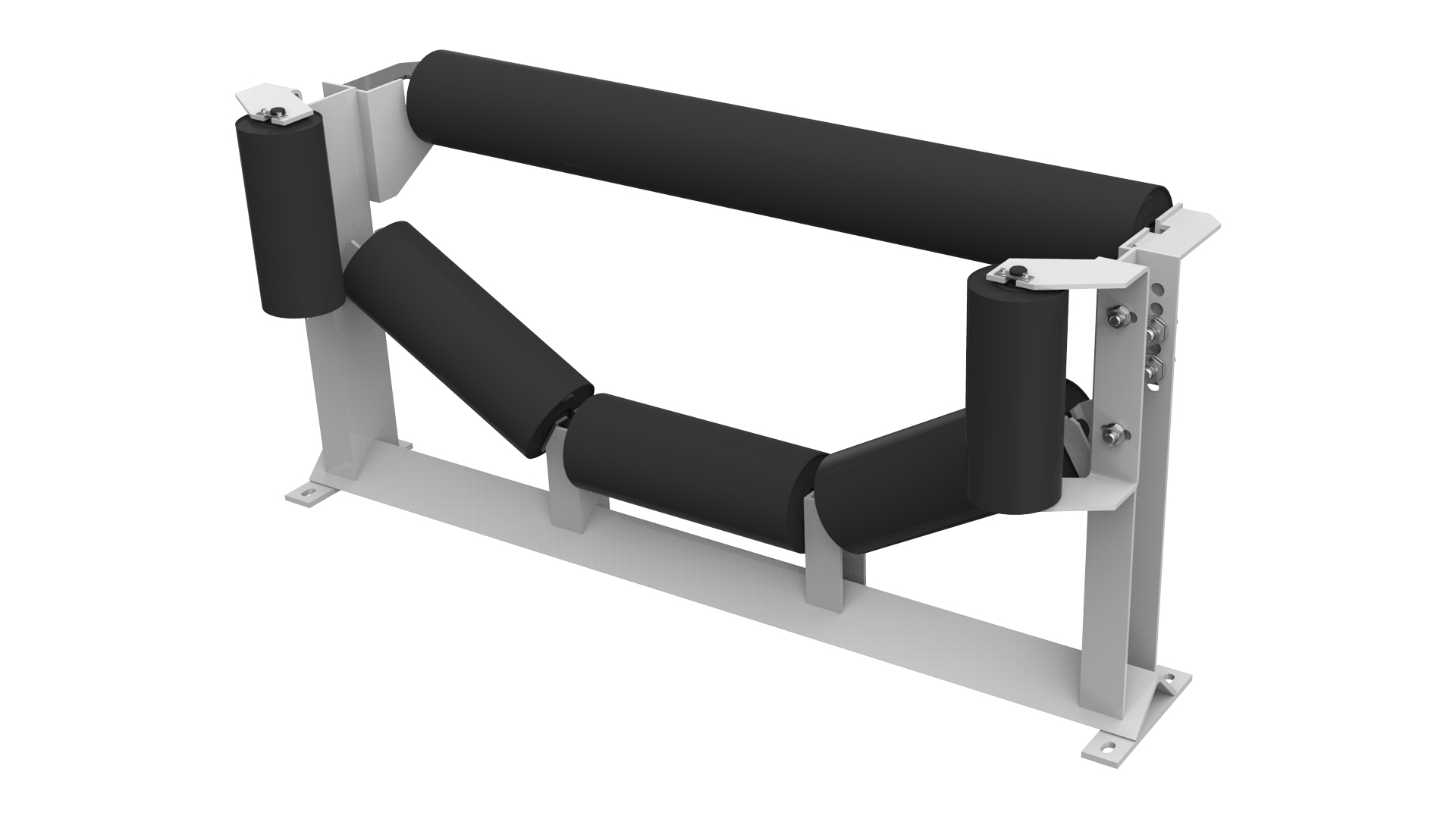

Center is impact roller

By adopting an "Impact roller" in the center roller section, the increase in running resistance of the belt is minimized, making it a product that does not impose an excessive burden.

-

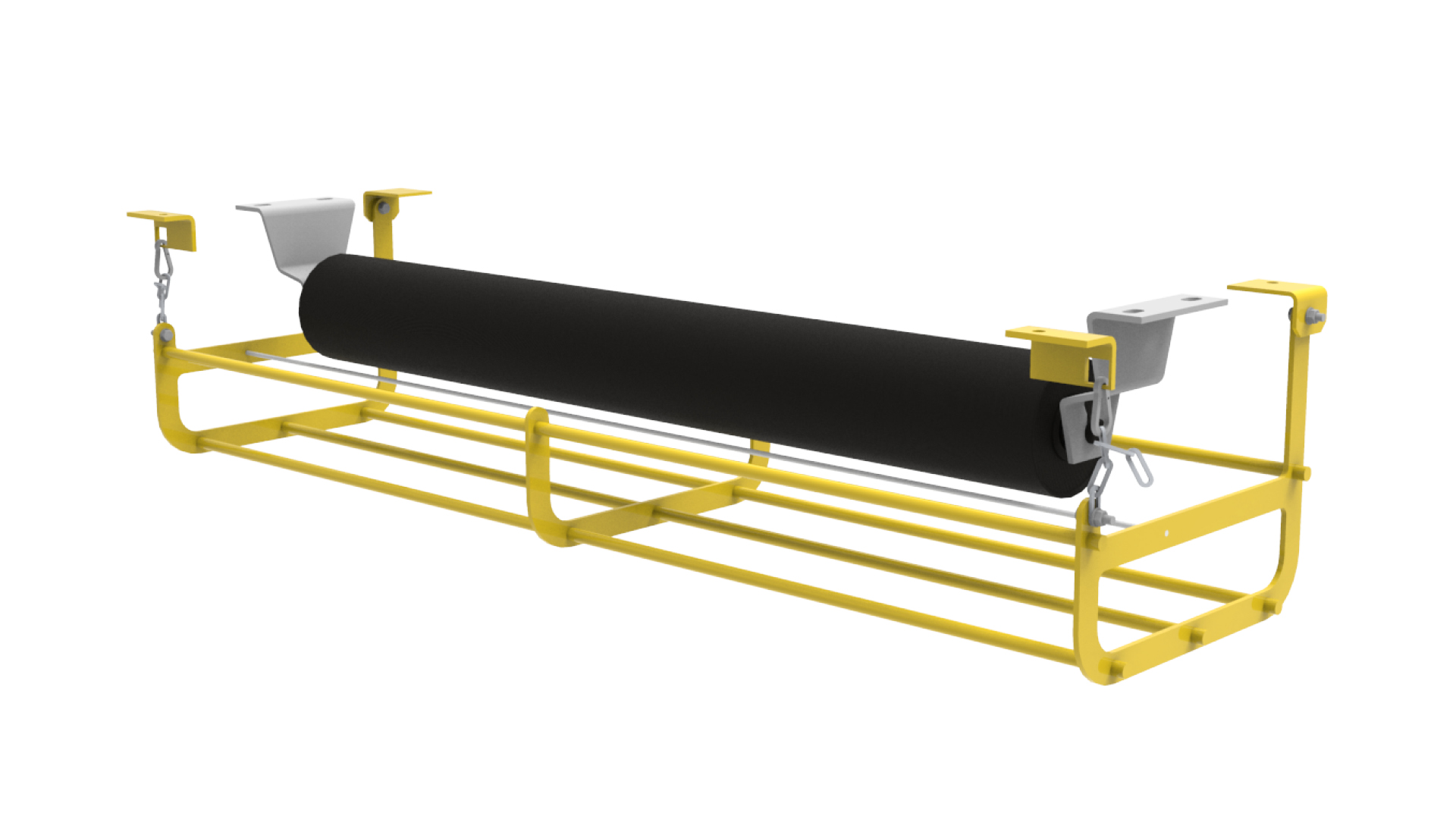

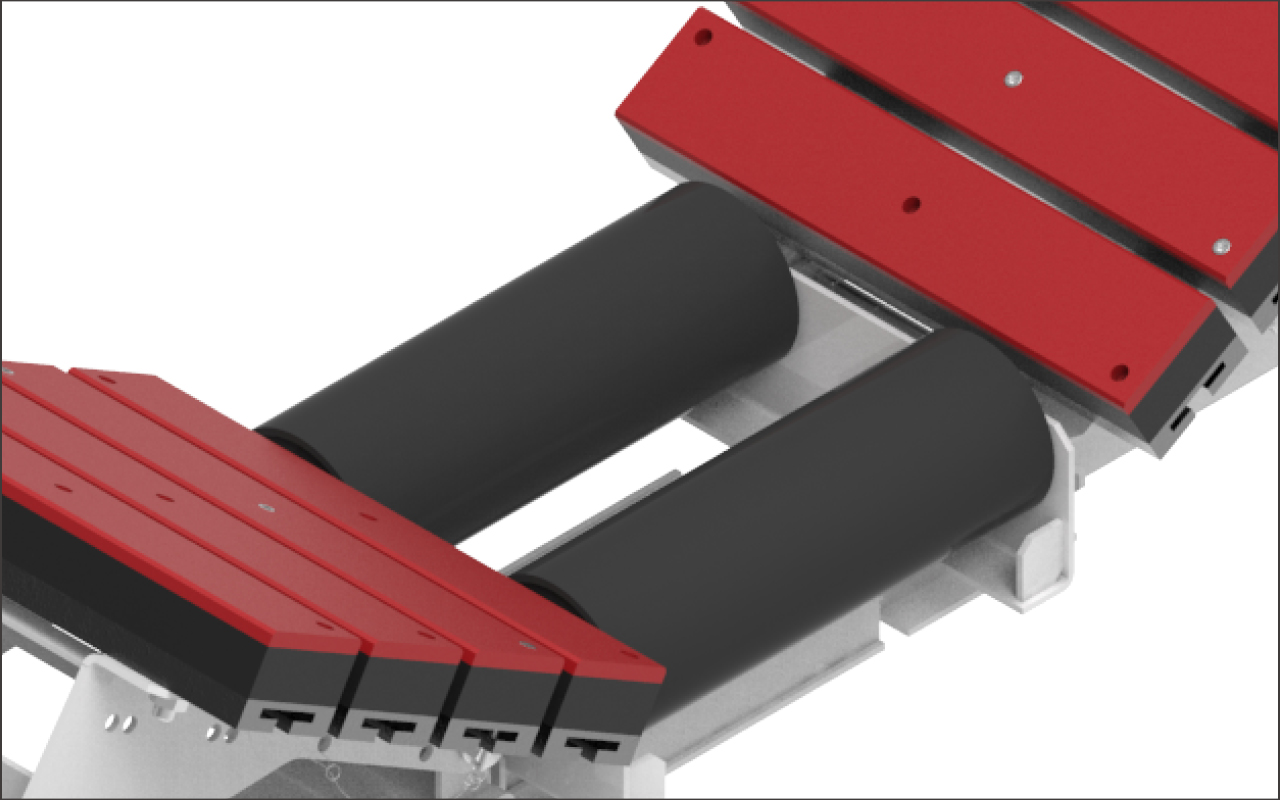

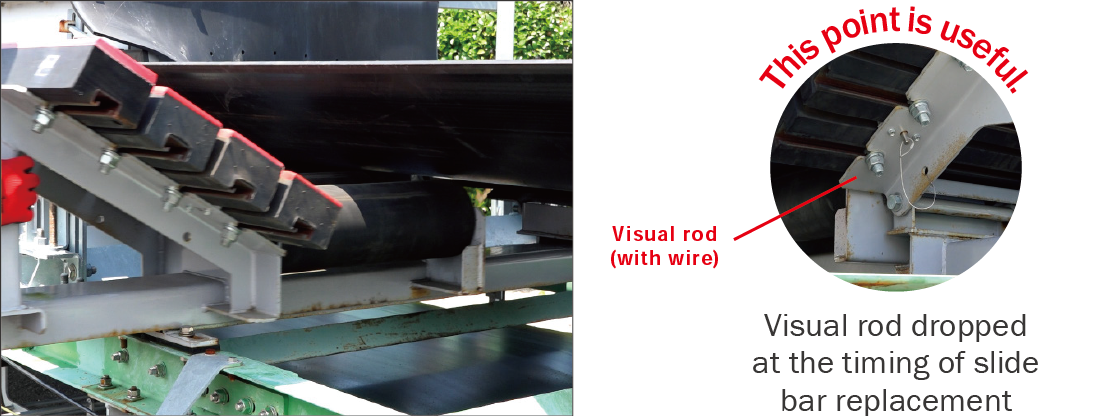

Easy replacement with drawer structure

The right and left slide bars and the center roller are of the "drawer structure" so that you can easily replace them if they are worn out.

The stand is divided into two sections and three sections.

Easy replacement with drawer structure

The right and left slide bars and the center roller are of the "drawer structure" so that you can easily replace them if they are worn out. The stand is divided into two sections and three sections.