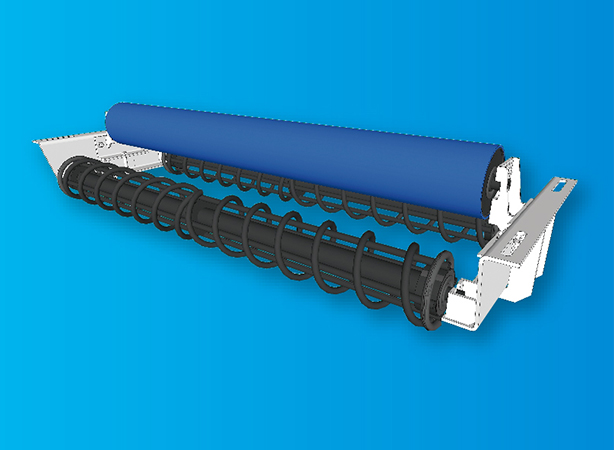

Scraping unit Idler

BSR type

Application・Function

This Unit consists of 1 Holding Roller and 2 Spiral Rollers. This unit has the function to enforce scraping off deposits on the Belt and promoting “mining”.

Selection Guide

For relatively “safe and maintenance” in conveyor equipment by setting up this product in an easy area as a “pit-dropping promotion area” and forcing the pit-dropping to be promoted, it becomes possible to perform safer and more efficient cleaning work. We are also able to manufacture brackets only.

Use Roller

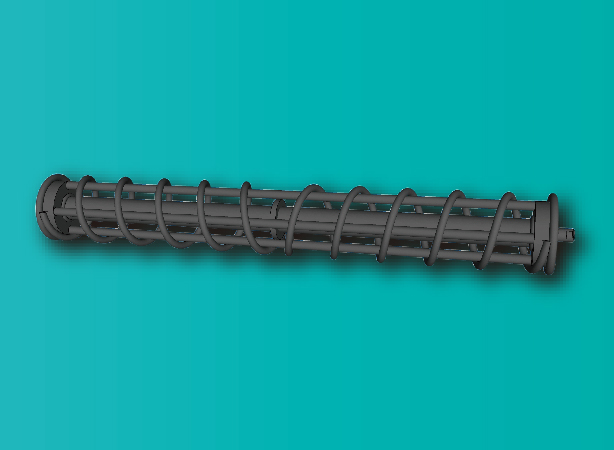

Spiral Return Roller SR type

Dangoless Return Roller RDL2 type

※To prevent the roller from sticking to the object to be transported, the standard specification sets the upper pressing roller to “Dangoless return roller.”

For high-viscosity conveyances, the Dangoless Return Rollers specification is effective for the two lower spiral return rollers.

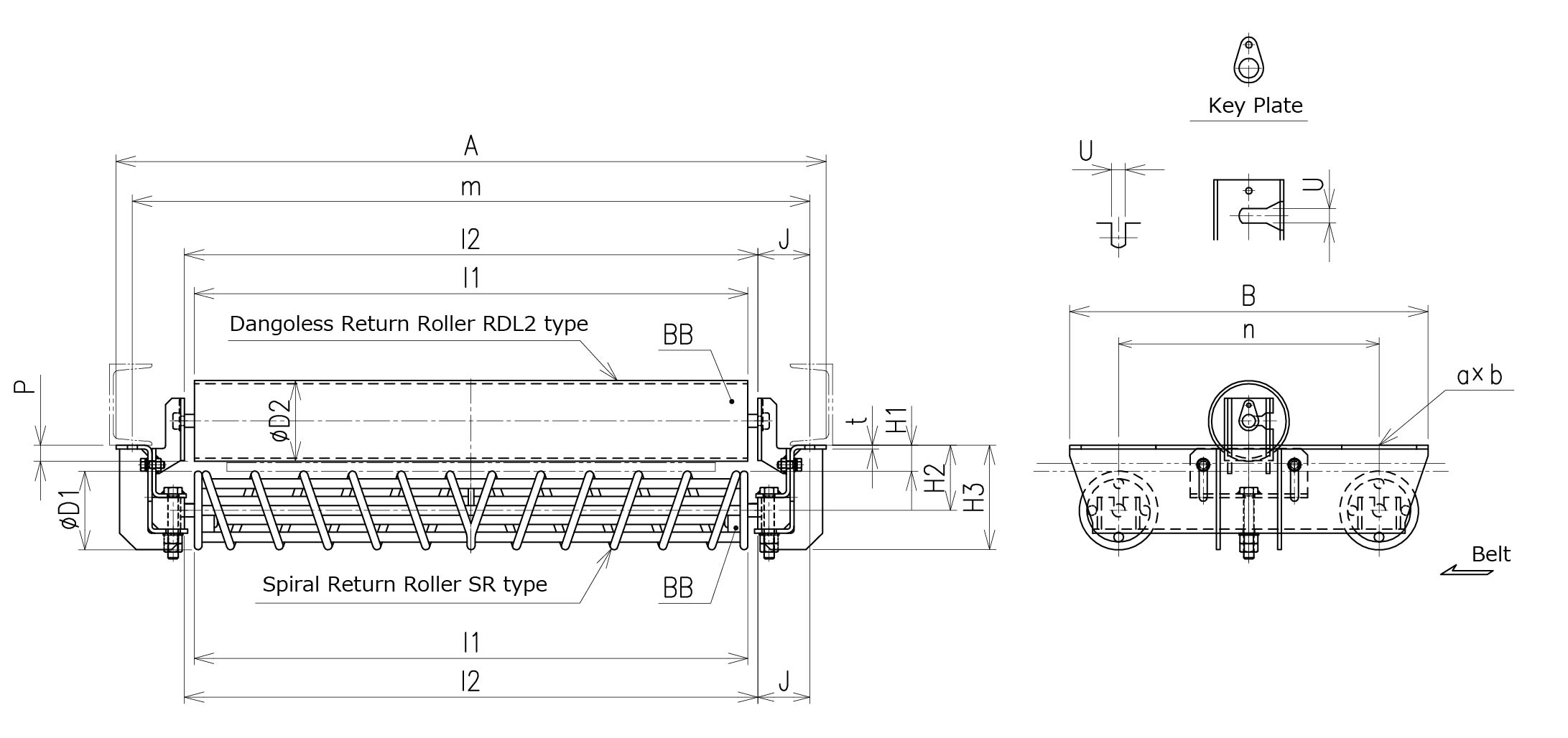

Idler Model Number

Outline Dimension

(mm)

|

B W

|

Model

|

H1

|

H2

|

H3

|

m

|

A

|

n

|

B

|

D1

|

D2

|

l 1

|

l 2

|

P

|

J

|

U

|

t

|

a×b

|

BB

|

Weight(kg)

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 400 | BSR-400 | 48 | 100 | 160 | 640 | 690 | 300 | 450 | 104 | 99 | 460 | 480 | 33~83 | 80 | 14.5 | 4.5 | 15×115 | 6204ZZ | 30.1 |

| 450 | BSR-450 | 48 | 100 | 160 | 690 | 740 | 300 | 450 | 104 | 99 | 510 | 530 | 33~83 | 80 | 14.5 | 4.5 | 15×115 | 6204ZZ | 31.9 |

| 500 | BSR-500 | 48 | 100 | 160 | 740 | 790 | 300 | 450 | 104 | 99 | 560 | 580 | 33~83 | 80 | 14.5 | 4.5 | 15×115 | 6204ZZ | 33.6 |

| 600 | BSR-600 | 48 | 100 | 160 | 840 | 890 | 300 | 450 | 104 | 99 | 660 | 680 | 33~83 | 80 | 14.5 | 4.5 | 15×115 | 6204ZZ | 36.8 |

| 750 | BSR-750 | 40 | 100 | 160 | 1040 | 1090 | 400 | 550 | 121 | 124 | 850 | 880 | 25~75 | 80 | 14.5 | 6 | 15×115 | 6204ZZ | 58.7 |

| 900 | BSR-900 | 40 | 100 | 160 | 1190 | 1240 | 400 | 550 | 121 | 124 | 1000 | 1030 | 25~75 | 80 | 14.5 | 6 | 15×115 | 6204ZZ | 65.2 |

| 1050 | BSR-1050 | 46 | 120 | 185 | 1340 | 1390 | 450 | 600 | 148 | 150 | 1150 | 1180 | 26~76 | 80 | 18.5 | 6 | 15×115 | 6205ZZ | 98.2 |

| 1200 | BSR-1200 | 46 | 120 | 185 | 1490 | 1540 | 450 | 600 | 148 | 150 | 1300 | 1330 | 26~76 | 80 | 18.5 | 6 | 15×115 | 6205ZZ | 107.0 |

| 1400 | BSR-1400 | 64 | 150 | 235 | 1730 | 1790 | 550 | 710 | 172 | 175 | 1530 | 1550 | 36~86 | 90 | 22.5 | 9 | 19×119 | 6206ZZ | 175.9 |

| 1600 | BSR-1600 | 64 | 150 | 235 | 1930 | 1990 | 550 | 710 | 172 | 175 | 1730 | 1750 | 36~86 | 90 | 22.5 | 9 | 19×119 | 6206ZZ | 190.2 |