Features of JRC Standard Roller

Structure of JRC Standard Roller

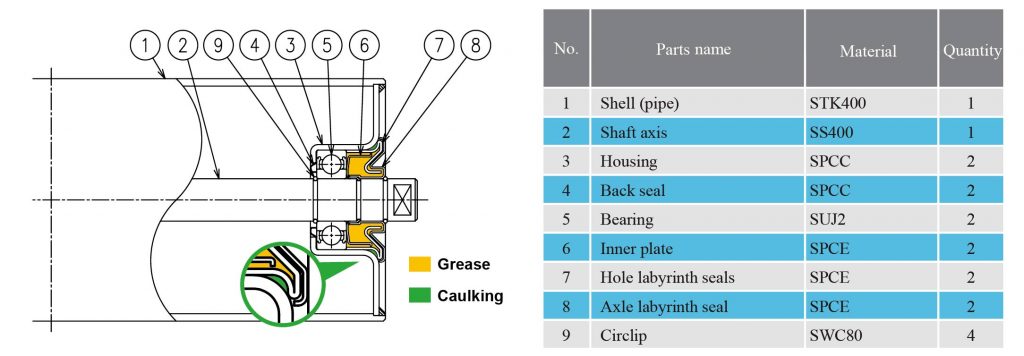

The inner construction of the JRC standard Roller of dimensions conforming to the JIS standard and JIS standard is as follows.

Feature of Parts of JRC Standard Roller

● Shell (pipe)

High-precision special materials are used and welded all around the housing to ensure sealing and strength. In addition, JRC’s original fully automated Roller Assembly Lines provide stable assembly, enabling the production of Rollers with extremely low rotational runout.

● Shaft

Specially designed cold finished Steel Bar based on JRC dimensional standards (tolerances) that are stricter than JIS standard are used. No roll or slippage between B earing and Shaft, which secure high-speed rotation and high load operation

● Housing

The press forming process is divided into several steps, and a strong Housing structure that strictly controls the accuracy of the fitting section enables a Roller with a small weight of the rotating section.

● Labyrinth seal

JRC has developed its own non-contact steel seals. When the Roller rotates, the labyrinth seal itself scrapes foreign materials out of the Roller. By combining it with a special grease, the Roller has excellent Dustproof and Waterproof performance.In addition, since the seal itself is fit into a groove formed in the shaft, it is resistant to a thrust load.

● Grease

Special Roller grease had been developed to fullfill JRC requirement in cooperation with grease manufacturers. JRC’s original grease, which is excellent in Dustproof and Waterproof character and has low initial resistance, fills the space of the non-contact labyrinth seal. (Operating temperature range:-25°C to 120°C)

● Caulking

It is applied between the housing and the labyrinth seal for holes to improve Dustproof and Waterproof performance.

Assembling Process of JRC Standard Roller

In JRC main Plant (Minami-awaji City, Hyogo Prefecture), the unique “three fully automated Roller assembly lines” in Japan have enabled us to achieve “non man” Roller manufacturing processes, from cutting pipes to assembling, welding, inspecting, finish painting and packaging. We have established a stable supply and prompt delivery system for high-precision Rollers with no variation in quality.