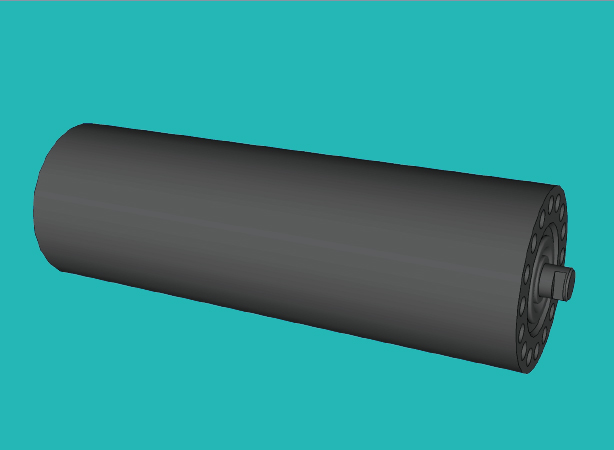

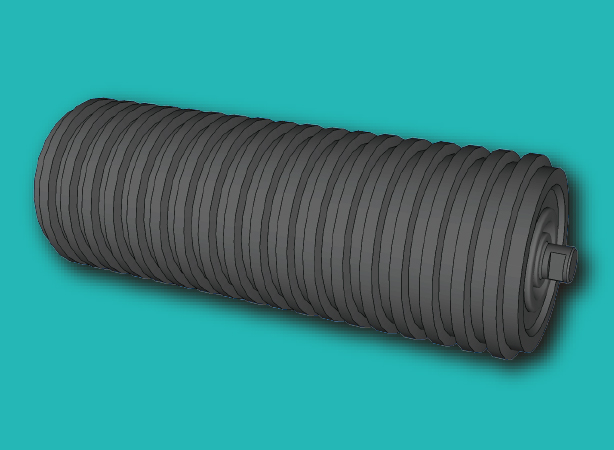

Impact Roller (T type)

KC-T types

Application・Function

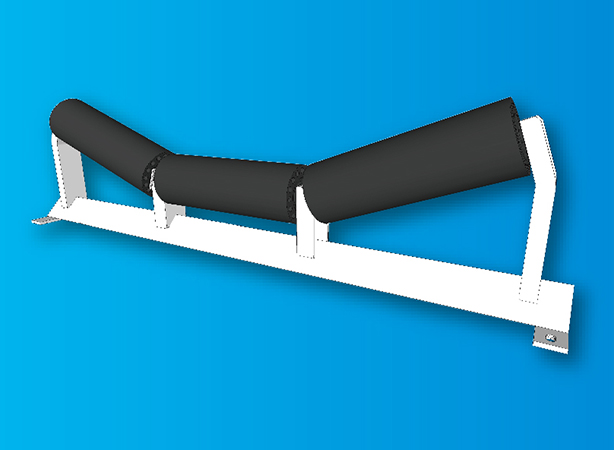

This Roller is used in the Idler at the point (impact section) where conveyed objects fall, such as hoppers and chute openings, on the conveyor. Hollow impact rubber is baked on a steel tube Roller, so that the surface does not peel off and the impact of dropping can be mitigated.

Selection Guide

Use the product in an impact Idler with a higher impact relaxation efficiency than the M-type product and a heavier specific gravity of 1.0t per m3 or more (iron ore, lump stone, limestone, etc.) or in a place where the impact of dropping is relatively large.

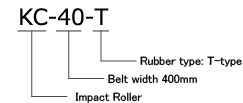

Model Number

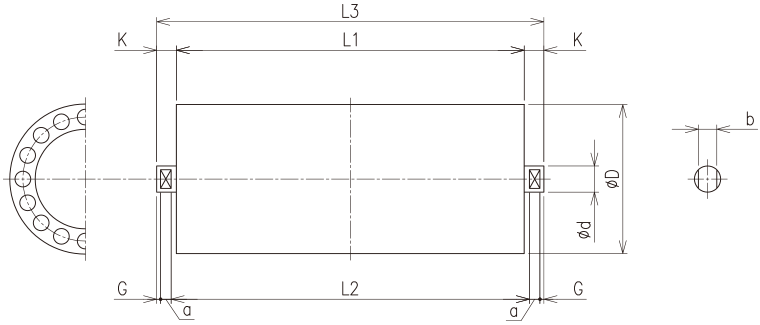

Outline Dimension

(mm)

|

B W

|

Model

|

D

|

L1

|

L2

|

L3

|

K

|

G

|

a

|

b

|

d

|

BB

|

Weight(kg)

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 400 | KC-40-T | 90 | 145 | 153 | 175 | 15 | 3 | 8 | 14 | 20 | 6204ZZ | 2.8 |

| 450 | KC-45-T | 90 | 165 | 173 | 195 | 15 | 3 | 8 | 14 | 20 | 6204ZZ | 3.1 |

| 500 | KC-50-T | 90 | 180 | 188 | 210 | 15 | 3 | 8 | 14 | 20 | 6204ZZ | 3.4 |

| 600 | KC-60-T | 90 | 210 | 218 | 240 | 15 | 3 | 8 | 14 | 20 | 6204ZZ | 3.9 |

| 750 | KC-75-T | 115 | 265 | 273 | 295 | 15 | 3 | 8 | 14 | 20 | 6204ZZ | 4.7 |

| 900 | KC-90-T | 115 | 315 | 323 | 345 | 15 | 3 | 8 | 14 | 20 | 6204ZZ | 5.5 |

| 1050 | KC-105-T | 140 | 370 | 380 | 410 | 20 | 4 | 11 | 18 | 25 | 6205ZZ | 8.7 |

| 1200 | KC-120-T | 140 | 420 | 430 | 460 | 20 | 4 | 11 | 18 | 25 | 6205ZZ | 9.7 |

| 1400 | KC-140-T | 166 | 500 | 510 | 540 | 20 | 4 | 11 | 22 | 30 | 6206ZZ | 17.3 |

| 1600 | KC-160-T | 166 | 580 | 590 | 620 | 20 | 4 | 11 | 22 | 30 | 6206ZZ | 19.7 |

| 1800 | KC-180-T | 166 | 650 | 660 | 690 | 20 | 4 | 11 | 25 | 35 | 6207ZZ | 22.6 |

| 2000 | KC-200-T | 166 | 730 | 740 | 770 | 20 | 4 | 11 | 25 | 35 | 6207ZZ | 25.1 |